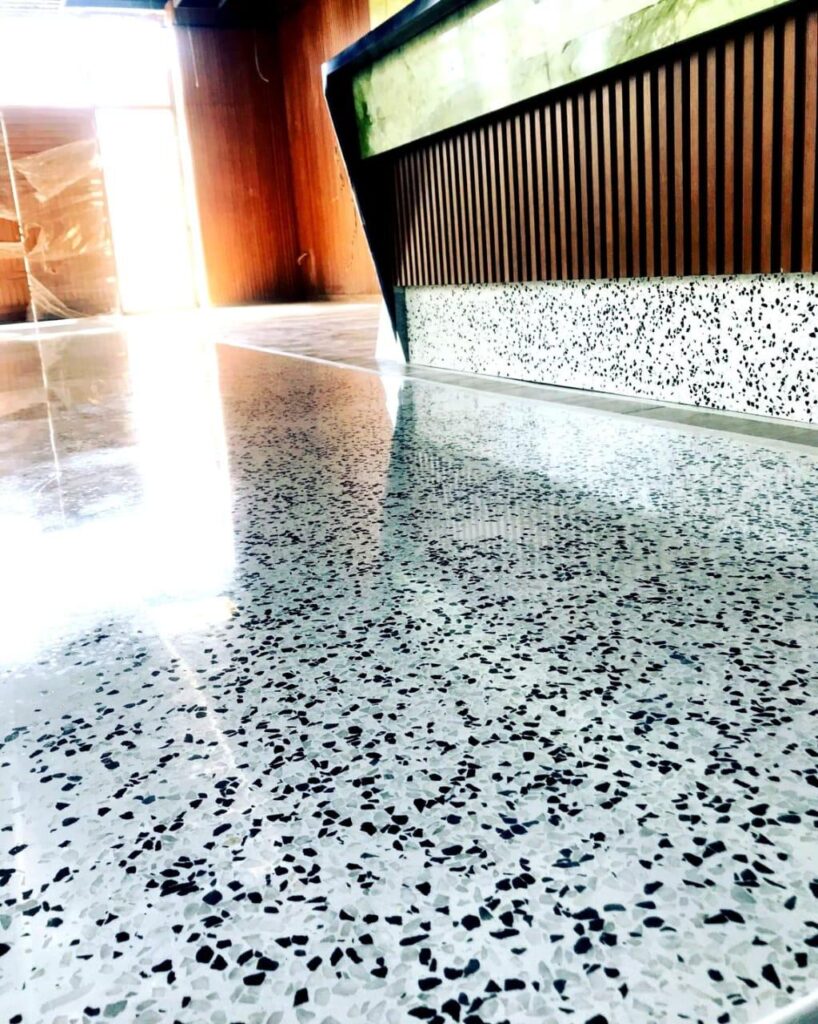

Cast on site Terrazzo (epoxy or cementitious)?

Choosing the right terrazzo floor—epoxy or cementitious—can feel overwhelming with so many options and risks. Worried about cracking, fading, or complicated installations? This is the ultimate guide to cast-on-site terrazzo choosing, backed by the proven expertise of Applicator Technical Services. Avoid costly mistakes and learn the secret to flawless, lasting terrazzo floors that transform your space.

Before you hire, don’t make this mistake—discover the complete truth about epoxy vs cementitious terrazzo to save thousands and get showroom-quality flooring!”

Frequently Asked Questions

What Is Cast-On-Site Terrazzo? What Are Epoxy and Cementitious Types?

Most asked question: What exactly is cast-on-site terrazzo, and how do epoxy and cement terrazzo compare?

Answer: Cast-on-site terrazzo is a seamless flooring method where aggregates like marble chips are mixed with a binder—either epoxy (resin) or cement—then poured and polished on location. Epoxy terrazzo is a lighter, stronger, and more vibrant option, ideal for high-traffic commercial areas due to its resistance to cracking, chemicals, and fading. Cementitious terrazzo is thicker, heavier, and traditionally used outdoors or in environments where natural, earthy tones are preferred.

| Feature | Epoxy Terrazzo | Cementitious Terrazzo |

| Thickness | 6-8mm onwards | 10mm onwards |

| Weight | Lighter, ideal for multi-floor usage | Heavier, requires solid base |

| Durability | Higher compressive/tensile strength | More prone to shrinkage/cracking |

| Color Range | Unlimited vibrant colors | Limited, earthy tones |

| Maintenance | Low, stain resistant | Higher upkeep, prone to efflorescence |

| Installation Time | Faster, less preparation needed | Slower, requires longer curing |

Warning signs: Avoid contractors who don’t test moisture or don’t prepare the substrate properly—this leads to cracking or lifting.

Next step: Schedule a detailed consultation with Applicator Technical Services to assess which type suits your application, budget, and design needs.

What Are The Most Common Installation Mistakes With Cast-On-Site Terrazzo?

Real worry: What are the costly mistakes that ruin terrazzo flooring projects?

Proven answers:

- Skipping or minimizing expansion joints causes cracked, loose tiles and unsightly damage.

- Incorrect waterproofing and moisture barriers lead to staining, warping, and adhesive failure.

- Poor base preparation or ignoring substrate moisture content weakens adhesion and causes bubbling or delamination.

- Using subpar aggregates or wrong binder ratios results in uneven texture and reduced aesthetics.

- Rushing grinding and polishing phases leave dull or uneven finishes that degrade quickly.

Red flags: Flaking, discoloration, or soft spots indicate poor workmanship or materials.

Next step: Trust Applicator Technical Services for end-to-end project management—our strict prep and quality control keep these risks in check.

How Does Applicator Technical Services Handle Cast-On-Site Terrazzo Projects?

Common query: What’s the step-by-step proven process for flawless cast-on-site terrazzo?

Complete process:

- Substrate Inspection & Moisture Testing: Critical for long-lasting adhesion.

- Surface Preparation: Repair cracks, level uneven spots, install expansion joints.

- Mixing Terrazzo Blend: Customized aggregates with epoxy or cement binders for design and durability needs.

- Pouring & Spreading: Even application with precise thickness control, including adding divider strips for design patterns.

- Curing: Proper curing conditions to avoid shrinkage, cracking or adhesion failure.

- Grinding & Polishing: Multi-stage grinding to reveal aggregates and smoothen.

- Sealing: Apply high-quality sealers for stain resistance, longevity, and shine.

- Final Inspection & Client Walkthrough: Making sure everything meets the highest standards.

Mistake to avoid: Trying to speed through any step compromises quality, leading to costly repairs.

Next step: Book your project evaluation with Applicator Technical Services—experience and precision make all the difference.

How Should I Maintain Cast-On-Site Terrazzo Floors?

Real concern: What care does cast-on-site terrazzo need?

Expert advice: Epoxy terrazzo demands less maintenance than cementitious. Routine cleaning with neutral pH cleaners avoids dulling or etching; avoid harsh chemicals. Periodic resealing helps protect against stains and wear, especially in commercial or high-traffic residential areas.

Red flag: Discoloration or surface degradation reveal improper sealing or cleaning.

Next step: Applicator Technical Services offers tailored maintenance programs that extend your floor’s lifespan and beauty.

Why Choose Applicator Technical Services for Your Terrazzo?

- Proven expertise in both epoxy and cementitious terrazzo systems tailored to UAE conditions.

- Transparent communication, personalized design assistance, and turnkey project delivery.

- Use of premier aggregates, binders, and sealers for lasting beauty and strength.

- Post-installation support and maintenance guidance for peace of mind.

Before you hire!

Contact Applicator Technical Services for your free terrazzo flooring consultation and quote. Don’t risk compromise on durability or design; this could save you thousands and deliver floors you’ll love for decades!

“Start your flawless terrazzo journey with Applicator Technical Services—trusted flooring experts for cast-on-site epoxy and cement terrazzo in the UAE!”

Contact us today to discover how these innovative flooring solutions can add character and performance to your space while providing decades of reliable service.

Call us on: +971 56 9973515 or +971 4 326 4341

Email us: info@applicatortech.com